Improve Data Quality, Integrity, and Traceability with Real-Time Capture

Labstep is a modern, R&D cloud ELN software system that uses interactive step-by-step protocols as templates for data collection to capture and structure all your research’s data and metadata in real-time. Our platform helps keep laboratory data structured, clean, and traceable in one secure environment, so modern R&D labs can better execute experiments, simplify compliance, and protect their IP.

One Environment, Unlimited Possibilities

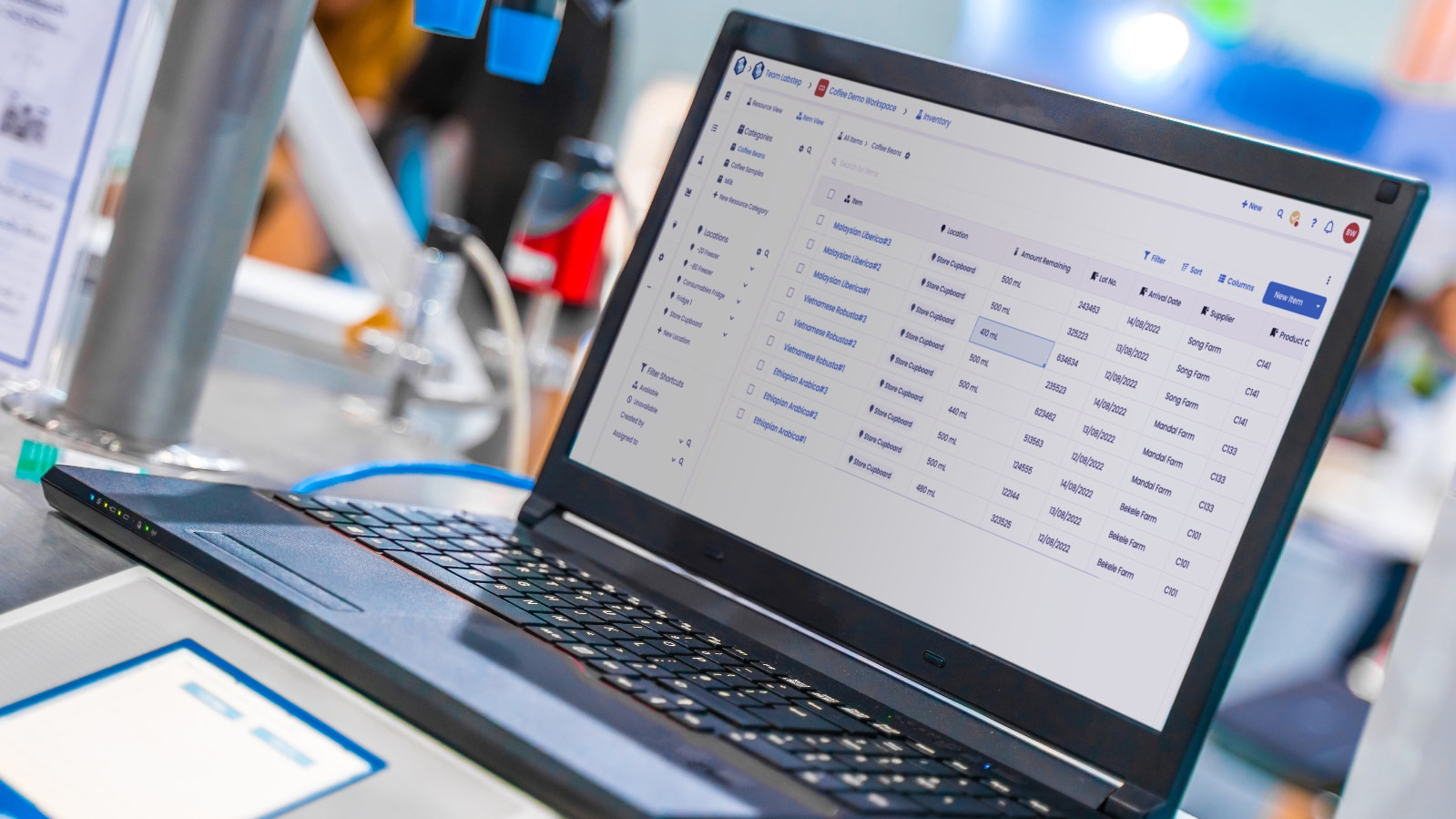

Eliminate data transfer by centralizing your lab notebook, protocols, samples, inventory, devices, and order management in one place with our fully connected, Labstep ELN software system. Whether you’re doing molecular, chemical, biological, or other scientific research, our solution has the templates and calculation engines you need to do multidisciplinary science in one system.

With version-controlled interactive protocols, full-featured inventory management, and easy integration with other instruments and devices, managing and executing complex experiments has never been simpler than with the STARLIMS electronic laboratory notebook.

Collaborate Anywhere, Anytime, on Any Device

The Labstep electronic laboratory notebook is a cloud-based web app that allows for collaboration no matter where you are. Global teams across any scientific discipline can share workspaces, collaborate on experiments, manage samples, and communicate in real time, accelerating R&D and eliminating the inefficiencies that slow research down. STARLIMS’s modern and intuitive interface is easy to adopt and delivers the transparent, knowledge sharing capabilities your team needs to get science done faster.

“Labstep is the most intuitive and easy-to-use ELN platform available.”

Carl Brown, Scientist, Sherlock Biosciences

“Labstep has vastly improved the security and traceability of our system, as well as allowing us to have a database of samples that can be extracted and used to make out analysis lists.”

Marianna Mirabelli, Director of Clinical Development, Elypta

“It’s helpful to be able to to cross reference things and collaborate. This allows us to jump in and out of each others experiments easily.”

Peter Baillie-Benson, Senior Laboratory Research Scientist, Francis Crick Institute

Fill in the Form to Contact Us

Resources

STARLIMS Spends 4 Quarters as G2 Leader in Lab Informatics

STARLIMS has maintained its position as G2 leading Lab Informatics provider for four consecutive quarters, leading in ELN, LIMS, and SDMS.

Webinar | Revolutionizing Research with ELN-Driven Experiment Efficiency

R&D leaders face growing pressure to innovate quickly and cost-effectively. However, manual paper-based data collection methods stifle innovation, while outdated systems slow productivity and introduce data quality and traceability issues. We explored this topic in our webinar.

Elypta Accelerates R&D for Cancer Detection with the Labstep ELN from STARLIMS

Elypta is on a mission to revolutionize early cancer detection with a pioneering metabolism-based liquid biopsy. Elypta’s research relies heavily on the simultaneous analysis of thousands of samples, posing significant challenges in managing, updating, and tracking these effectively.

Get to Know Labstep: A Q&A with the Heads of Product and Customer Success

We sat down with Labstep’s Barney Walker and Jenny Hu to discuss their backgrounds and learn why they’re excited to join STARLIMS.

Winter 2024 STARLIMS Maintains #1 LIMS Leader G2 Ranking

STARLIMS has maintained its position as G2’s #1 LIMS provider, further solidifying our position as the preferred choice for enterprise companies seeking superior laboratory informatics solutions. This fall, STARLIMS also skyrocketed to the top of G2’s SDMS report as the #1 provider and leader in the space.

The Labstep Electronic Lab Notebook (ELN) Solution Brief

R&D is critical in driving the innovations that improve our lives. Ideate, create, and protect your IP with the Labstep ELN.