Improve Data Flow, Accuracy, and Integrity

Our Laboratory Execution System streamlines laboratory operations, improves data accuracy, and helps you make better decisions, faster. With the ability to easily document work in real-time, LES enables SOP compliance, improves efficiency, and reduces transcription errors.

Our Laboratory Execution System system is intuitive and easy to use, making it effortless for lab teams to quickly adopt and start seeing results.

Extend the LIMS Beyond the Bench

STARLIMS Laboratory Execution System extends your LIMS beyond the lab, providing a seamless, mobile-optimized system that helps your team efficiently follow and execute SOPs with ease. LES provides support for your laboratory team, so processes are conducted according to predefined methods and standards, enhancing productivity and simplifying compliance.

Transform Laboratory Operations

By integrating into the R&D Quality Manufacturing LIMS or Clinical LIMS, LES allows you to automatically capture data from instruments and devices, quickly review and approve tests before data is sent to the LIMS, and track and manage samples and reagents.

Our Laboratory Execution System system is intuitive and easy to use, making it effortless for lab teams to quickly adopt and start seeing results.

With STARLIMS LES, you can empower your laboratory to achieve unparalleled efficiency, setting new benchmarks in laboratory excellence. Discover the power of STARLIMS Laboratory Execution System and redefine what’s possible in your lab operations.

Resources

G2 Winter 2025: STARLIMS Excels in LIMS and Beyond

STARLIMS is recognized for excellence in Lab Informatics, according to customer reviews on G2.

LIMS Best Practices: Six Steps to Success

To truly harness the power of LIMS, you need to implement best practices that will unlock its full potential.

Newform Foods Shapes Tomorrow’s Food Landscape with Support from Labstep, a STARLIMS Company

Newform Foods has digitalized its R&D efforts with the Labstep ELN, increasing productivity, collaboration and knowledge sharing, and data security.

WEBINAR | Driving R&D Experiment Efficiency Through the User Experience

Driving experiment efficiency starts with a better user experience. Learn how UX can simplify experiment execution and accelerate R&D.

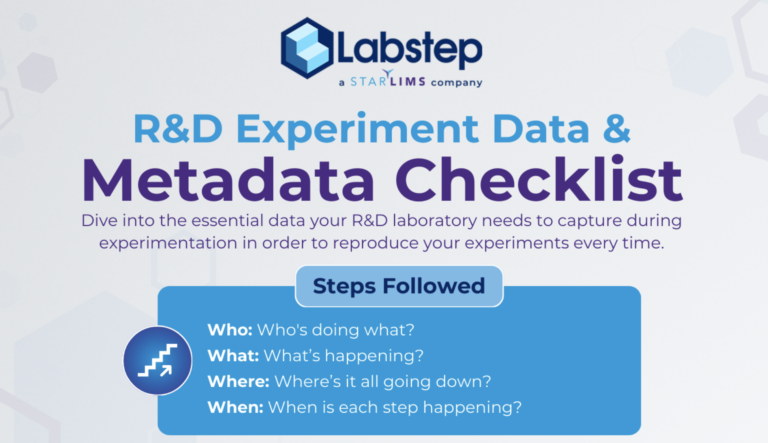

Infographic: R&D Experiment Data Capture Checklist

A comprehensive experiment record isn’t just about collecting information. It’s about ensuring that data is actionable, traceable, and meaningful.

WEBINAR | Advancing R&D with Collaboration

Learn how R&D labs can fan the flames of innovation with collaboration and cross-discipline science.